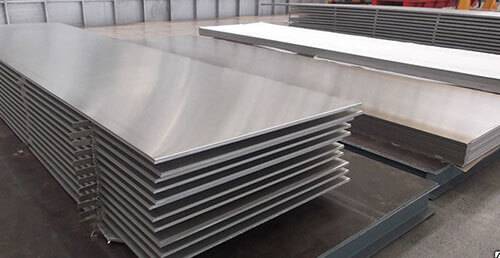

304 stainless steel sheet is one of the most widely used stainless steel products across industries. Known for its excellent corrosion resistance, strength, and versatility, it is often considered the “workhorse” grade of stainless steel. From fabrication and construction to food processing and chemical equipment, 304 stainless steel sheets deliver reliable performance at a reasonable cost.

What Is 304 Stainless Steel Sheet?

304 stainless steel is an austenitic stainless steel alloy containing approximately 18% chromium and 8% nickel. This chemical composition provides strong resistance to corrosion and oxidation while maintaining good formability and weldability.

When supplied in sheet form, it becomes ideal for applications requiring flat surfaces, precise fabrication, and clean finishes.

Key Properties of 304 Stainless Steel Sheet

Excellent Corrosion Resistance

304 stainless steel sheets resist rust and corrosion in most atmospheric environments, water exposure, and many chemicals. This makes them suitable for both indoor and outdoor applications.

High Strength and Durability

Despite being easy to form, 304 stainless steel offers good tensile strength and long service life, even under mechanical stress.

Good Weldability and Formability

The material can be easily welded using standard methods and formed into complex shapes without cracking, making it ideal for fabrication work.

Temperature Resistance

304 stainless steel sheets perform well at both high and low temperatures, retaining strength and toughness over a wide range.

Hygienic and Easy to Clean

Its smooth surface finish makes it resistant to bacterial growth, which is why it is commonly used in food, dairy, and pharmaceutical industries.

Common Uses of 304 Stainless Steel Sheets

Construction and Architecture

Used in cladding, handrails, panels, and decorative elements due to its strength and attractive appearance.

Food Processing and Kitchen Equipment

Ideal for sinks, countertops, storage tanks, and food preparation surfaces because of its hygiene and corrosion resistance.

Industrial Fabrication

Widely used in manufacturing tanks, enclosures, machine components, and general fabrication work.

Chemical and Pharmaceutical Equipment

Suitable for vessels, piping covers, and equipment exposed to mild chemicals.

Automotive and Transportation

Used in trims, panels, and structural components requiring corrosion resistance and durability.

Benefits of Using 304 Stainless Steel Sheet

-

Long-lasting and low maintenance

-

Cost-effective compared to higher alloy grades

-

Easy to fabricate and weld

-

Suitable for a wide range of industries

-

Good aesthetic appeal with various surface finishes

These benefits make 304 stainless steel sheets a preferred choice for both heavy-duty and decorative applications.

304 Stainless Steel Sheet vs Other Grades

Compared to carbon steel, 304 stainless steel offers superior corrosion resistance and longevity. When compared to 316 stainless steel, 304 is more economical and sufficient for most general-purpose applications, except in highly corrosive environments like marine or chloride-rich conditions.

Conclusion

When selecting material for fabrication and construction projects, quality and consistency play a critical role in overall performance. Many industries rely on a trusted 304 stainless steel sheet manufacturer to supply sheets that meet required thickness tolerances, surface finish standards, and mechanical properties. Using high-quality material helps reduce fabrication issues, improves corrosion resistance, and ensures long-term durability in demanding applications such as food processing equipment, architectural structures, and industrial enclosures.