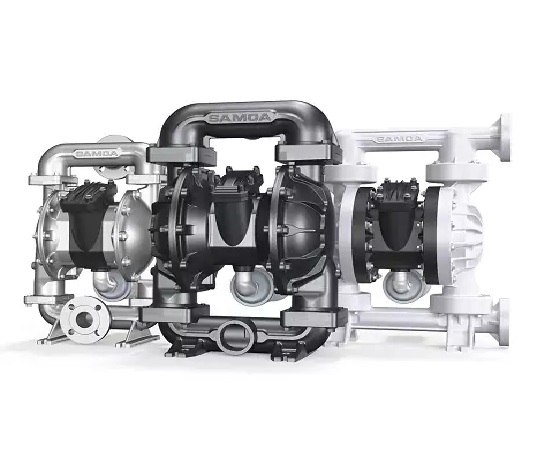

Diaphragm Pump

In the realm of fluid handling, efficiency, reliability, and versatility are key. Among the various technologies available today, the diaphragm pump has emerged as a standout solution, driving innovation across multiple industries. From chemical processing to wastewater management, and even food and pharmaceuticals, diaphragm pumps are reshaping how fluids are moved, controlled, and managed. But what makes this pump so essential, and why is it becoming a trending topic in industrial applications? Let’s dive deeper.

What is a Diaphragm Pump?

A diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a flexible diaphragm to move fluids. Unlike centrifugal pumps that rely on rotational energy, diaphragm pumps create a pumping action through reciprocating movements. The diaphragm’s flexing action generates suction and discharge, allowing the pump to handle a wide range of fluids—including viscous, abrasive, and chemically aggressive liquids.

These pumps are designed to operate in environments where conventional pumps may fail. Their ability to handle solids-laden fluids, high viscosity liquids, and corrosive chemicals makes them indispensable in challenging industrial settings.

Types of Diaphragm Pumps

Diaphragm pumps are broadly categorized into two main types:

-

Air-Operated Double Diaphragm (AODD) Pumps

-

These pumps use compressed air to drive two diaphragms alternately.

-

Ideal for hazardous or explosive environments because they do not require electricity.

-

Can handle high-viscosity fluids and solids without damage.

-

-

Mechanical Diaphragm Pumps

-

Driven by a crankshaft or eccentric mechanism that physically moves the diaphragm.

-

Typically used for precise dosing or in situations where continuous pumping is needed.

-

Often employed in chemical dosing, paint spraying, or oil pumping applications.

-

Advantages of Diaphragm Pumps

The popularity of diaphragm pumps has surged due to several compelling advantages:

1. Versatility in Fluid Handling

Diaphragm pumps can handle almost any type of liquid, from water to harsh chemicals. They are especially effective with slurries, viscous fluids, and fluids containing solids. This makes them indispensable in industries like mining, wastewater management, and chemical processing.

2. Leak-Free Operation

Unlike traditional pumps, diaphragm pumps have no seals that can leak. The fluid is contained entirely within the pump chamber, minimizing environmental hazards and workplace contamination. This feature makes them ideal for pumping toxic, corrosive, or hazardous substances.

3. Self-Priming Capability

Diaphragm pumps can self-prime, meaning they can start pumping even when the inlet line is empty. This saves time, reduces downtime, and allows for more flexible installation options.

4. Dry-Run Capability

Some diaphragm pumps can run dry without damaging the pump components, unlike centrifugal pumps that risk overheating or cavitation if run without fluid. This feature is particularly valuable in industries where the fluid supply may be inconsistent.

5. Energy Efficiency

Air-operated diaphragm pumps can be more energy-efficient in intermittent operation scenarios. Mechanical diaphragm pumps provide precise fluid dosing, reducing waste and improving process efficiency.

Applications of Diaphragm Pumps

The wide-ranging capabilities of diaphragm pumps have made them essential across various sectors:

1. Chemical Industry

Diaphragm pumps are widely used for transferring acids, solvents, and other corrosive chemicals safely. Their leak-proof design ensures safe handling of dangerous fluids, preventing workplace accidents.

2. Food and Beverage Industry

Hygienic diaphragm pumps are used to transport viscous food products like syrups, sauces, and dairy products. These pumps maintain product integrity and comply with strict sanitation standards.

3. Water and Wastewater Management

In water treatment plants, diaphragm pumps efficiently handle sludge, chemicals, and wastewater, making them crucial for municipal and industrial water management systems.

4. Oil and Gas Industry

Diaphragm pumps are ideal for transferring crude oil, fuel, and lubricants. Their ability to handle high-viscosity fluids and solids ensures reliable operations in extraction, refining, and transport.

5. Mining and Construction

These pumps are robust enough to handle abrasive slurries and mud, making them indispensable in mining and construction operations where heavy-duty fluid pumping is required.

6. Pharmaceutical and Cosmetics

For dosing chemicals and transferring delicate fluids, diaphragm pumps provide precise, contamination-free fluid handling, ensuring high-quality production standards.

Recent Trends in Diaphragm Pump Technology

With industries seeking more efficient, sustainable, and automated solutions, diaphragm pump technology is evolving rapidly:

-

Smart Pumps with IoT Integration

Modern diaphragm pumps are now being integrated with IoT sensors for real-time monitoring. Parameters like flow rate, pressure, and diaphragm wear can be tracked digitally, enabling predictive maintenance and minimizing downtime. -

Energy-Efficient Designs

Manufacturers are developing pumps with optimized air and mechanical efficiency, reducing energy consumption without compromising performance. -

Materials Innovation

Advanced materials such as PTFE, EPDM, and stainless steel are used to enhance chemical resistance and longevity, expanding the range of fluids that pumps can safely handle. -

Compact and Modular Systems

Space-saving, modular diaphragm pumps allow easy installation and scalability, especially for industries with limited floor space or evolving production needs.

How to Choose the Right Diaphragm Pump

Selecting the correct diaphragm pump requires understanding the fluid characteristics, flow requirements, and operating environment. Key factors include:

-

Fluid Type: Is it corrosive, abrasive, or viscous?

-

Flow Rate and Pressure: Determine the required performance to meet operational needs.

-

Material Compatibility: Ensure pump components resist chemical attack and wear.

-

Power Source: Air-operated vs. mechanical, depending on electricity availability and safety requirements.

-

Maintenance Needs: Consider ease of diaphragm replacement and monitoring capabilities.

Consulting with experts or suppliers can ensure the pump meets your specific operational needs while maximizing efficiency and safety.

Conclusion

The diaphragm pump is no longer just another piece of industrial equipment—it is a versatile, reliable, and essential technology that drives efficiency across numerous sectors. Its ability to handle challenging fluids, operate safely under harsh conditions, and integrate with modern monitoring systems makes it a trending topic in fluid handling technology.

As industries continue to demand innovative solutions for safer, more efficient, and environmentally responsible operations, diaphragm pumps are poised to lead the charge. Investing in the right diaphragm pump not only enhances operational performance but also ensures long-term sustainability and compliance with stringent industry standards.

Whether you are in chemicals, food and beverage, water treatment, or pharmaceuticals, diaphragm pumps are shaping the future of fluid management—one pulse at a time.