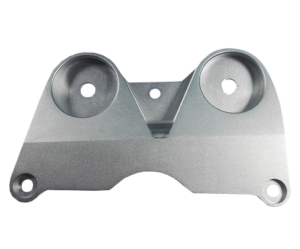

Precision CNC services provide manufacturers with the capability to produce high-quality, complex parts with exceptional accuracy. These services utilize advanced computer numerical control (CNC) technology and state-of-the-art machinery to ensure that each part meets the stringent standards required for a wide range of industries.

The Benefits of Precision CNC Services

One of the key benefits of precision CNC services is their ability to deliver consistent results, even for the most intricate and demanding projects. CNC machines are programmed to follow precise instructions with incredible accuracy, allowing for the creation of highly detailed and complex parts that would be nearly impossible to produce using traditional machining methods. This level of precision is essential for industries such as aerospace, automotive, and medical, where even the smallest deviation in a part’s dimensions can have serious consequences.

Consistency and Repeatability

In addition to accuracy, precision CNC services also offer unmatched consistency and repeatability. Once a part has been programmed and tested, the CNC machine can reproduce it with identical precision every time. This level of reliability is crucial for ensuring that all parts in a production run are uniform and meet the required specifications. It also eliminates the need for manual adjustments or rework, saving time and reducing the risk of errors.

Material Versatility and Flexibility

Furthermore, precision CNC services are capable of handling a wide variety of materials, including metals, plastics, and composites. This versatility allows manufacturers to choose the most suitable material for their specific application, whether it requires strength, durability, or lightweight properties. CNC machines can also be equipped with a range of cutting tools and accessories to accommodate different materials and achieve the desired surface finishes.

Streamlining Production and Reducing Lead Times

Another advantage of precision CNC services is their ability to streamline the production process and reduce lead times. CNC machines operate continuously and can run unattended for extended periods, significantly increasing productivity compared to traditional machining methods. This efficiency not only saves time but also allows manufacturers to meet tight deadlines and respond quickly to changes in demand.

Quality Control and Assurance

Furthermore, precision CNC services ensure that each part is manufactured with the highest level of quality and durability. CNC machines are equipped with advanced monitoring and inspection systems that check each part during and after production to ensure that it meets the specified tolerances. This quality control process helps prevent defects and ensures that all parts are reliable and long-lasting, reducing the risk of failures or costly recalls.

Conclusion

In conclusion, precision CNC services play a vital role in meeting the demands for excellence and durability in today’s manufacturing industry. By utilizing advanced technology and machinery, these services deliver exceptional accuracy, consistency, and quality for even the most complex projects. Whether producing components for aerospace, automotive, or medical applications, manufacturers can rely on precision CNC services to meet their high standards and deliver superior products to their customers.